System Introduction

Modern power engineering and thermal energy technology require high temperature-high pressure boilers to produce superheated steam with a very high degree of superheat. However, for some equipment process requirements, such steam may be too dry or superheated. For example: when the heat exchanger is used for process operation, the use of superheated steam reduces the efficiency due to the low heat transfer coefficient, and the use of saturated steam is more suitable. . In addition, when the high pressure dry saturated steam is decompressed to

At low pressure, superheat is created at the downstream outlet. All of this requires cooling the superheated steam to the desired near-saturation temperature, which requires a desuperheater.

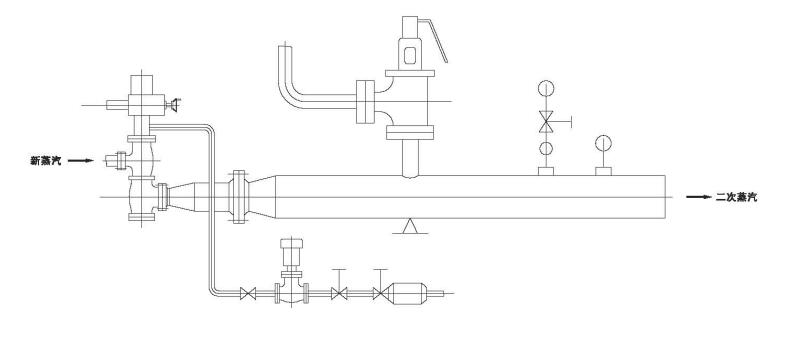

In many cases it is necessary to simultaneously reduce and depressurize the high pressure superheated steam. The desuperheating and decompression device is a high-efficiency and energy-saving environmental product. The desuperheating and decompression device is equipped with the corresponding industrial automation instrument (ie, thermal control cabinet), and the primary (new) steam pressure P1 delivered from power stations or industrial boilers and thermal power plants , The temperature t1 is decompressed and decompressed, so that the secondary steam pressure P2 and the temperature t2 meet the requirements of the production process.

It is widely used in thermal power plants, central heating, food industry, petrochemical industry, textile industry, rubber industry, paper and pulp industry, tobacco industry, pharmaceutical industry and other industries. In order to meet the requirements of different equipment and processes, our company provides different types of desuperheating and decompression devices (decompression, decompression), and realizes a full set of intelligent automatic control or DCS system networking.

Structural Classification

1. Integrated desuperheating and decompression device (WY type);

2. Split type desuperheating and decompression device (Y-W type);

3. Venturi desuperheating device (W08 type) ;

4. Adjustable spraying and desuperheating device (W408 type);

5. Ejection desuperheating device (W10 type) ;

6. Decompression device (Y05, Y06, Y07 type);

Note: Detailed technical parameters can be provided according to user needs.

Structural Classification

1. Imported Yan steam pressure

Medium temperature and pressure: P1≤3.82MPa, temperature t1 ≤450C;

Second high temperature and high pressure: P1≤5.4MPa, temperature t1 ≤485C;

High temperature and high pressure: P1≤10MPa, temperature t1≤540C;

2. Export traffic Q

The variation range of the outlet flow tQ of the temperature reduction and pressure reduction device is 10%Q~100%Q, and it is ideal to adjust within this range. If you have special requirements, you can negotiate with the company to decide.

3. Outlet steam pressure P2

The adjustment accuracy of outlet steam pressure P2 is not lower than 2.5.

4, outlet steam temperature t2

The adjustment accuracy of the outlet steam temperature t2 is not lower than 2.5.

5, noise

When the device is in normal operation, measure its noise one meter downstream of the temperature reducing and pressure reducing valve, and at the same time measure its noise at a distance of one meter away from the pipe wall, and the noise level should not be greater than 80 decibels.

Ordering Instructions

Please provide when ordering a contract:

1. Outlet steam flow IQ. Inlet steam pressure P1, temperature t1, outlet steam pressure P2, temperature [2;

2. Desuperheating water supply pressure Pb, temperature tb;

3. Indicate the control method: (Dashboard control, DCS control, DCS monitoring);

4. Control Category: Electric, Pneumatic

Also required when selecting a pneumatic valve;

1) Action form: air-open or air-closed;

2) Air source pressure;

3) Provide electrical valve positioner electrical signal;

4) Instructions for other attachments: If users have special requirements, they should indicate it after negotiating or sign a technical agreement separately.

Service Hotline

+86-513-87380886

Service Hotline

+86-513-87380886